Obsolescence and DMSMS Engineering

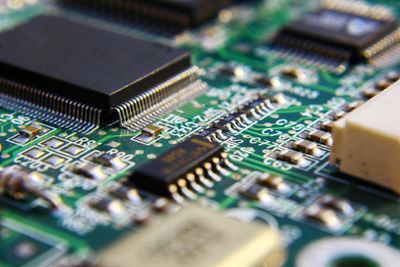

Keep legacy DLA and OEM systems supportable when parts go obsolete or suppliers disappear.

When key parts go EOL, your hardware still has to perform. We help engineering, program, and buyer teams pick the smallest viable change, prove it, and keep DLA / OEM customers comfortable with the evidence.

What this helps with:

- Making clear decisions when critical parts go end-of-life or suppliers shut down

- Avoiding rushed last-time-buys and ad-hoc substitutions that create future headaches

- Planning form/fit/function replacements that respect fielded hardware and approvals

- Supporting NSN spares, SAR paths, and long-term sustainment planning with real data

Typical deliverables:

- BOM and risk reviews focused on real sustainment pressure points

- Obsolescence roadmaps and replacement strategies across assemblies and NSNs

- Form/fit/function replacement concepts, design updates, and sanity checks

- Updated drawings, specs, and records aligned with configuration control and SAR evidence needs

What we need from you:

- Current BOMs, part lists, and any known problem parts or suppliers

- Available drawings, specs, ECOs, and configuration data (even if incomplete)

- Rough demand / usage expectations and any field or depot constraints that matter

- Any DLA / NSN, SAR, or packaging/marking context that decisions must support

We’ll review your inputs and send back a short Obsolescence Options Snapshot—no cost, no obligation.

Impact Circuit Designs™ is a trademark of Impact Circuit Designs, Inc.

Copyright © 2025 Impact Circuit Designs - All Rights Reserved.

CAGE: 1UWD4 | Veteran Owned and Operated