Prototype and Test Support

Turn concepts, replacements, and bridge modules into proven hardware that supports real approvals.

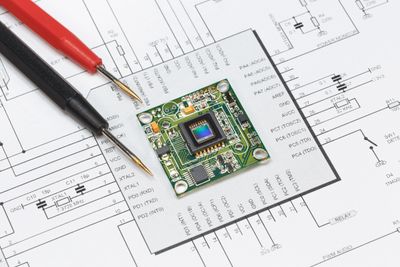

We help you prototype boards, harnesses, and bridge modules, then get them into the lab with practical fixtures and test plans. The goal: de-risk changes quickly so engineers, PMs, and buyers can move forward confidently.

What this helps with:

- De-risking new or replacement designs before committing to full production

- Proving form/fit/function for obsolescence and NSN spares decisions

- Sorting out bench behavior that doesn’t match drawings, datasheets, or expectations

- Building test evidence that can support SAR, source-approval, or buyer confidence

Typical deliverables:

- Prototype PCB and cable assemblies for evaluation and bring-up

- Test fixtures, adapter harnesses, and simple test benches for targeted checks

- Test plans aligned to acceptance vs qualification intent and fielded realities

- Test reports, data packages, and observations that feed SAR and spares decisions

What we need from you:

- Relevant drawings, schematics, BOMs, and any prior test reports

- Clear success criteria: what needs to be proven and for whom (DLA buyer, OEM, internal)

- Practical test constraints: available equipment, access to assets, schedule, and risk tolerance

- Any specific SAR, NSN, or approval requirements the prototypes and tests should support

Impact Circuit Designs™ is a trademark of Impact Circuit Designs, Inc.

Copyright © 2025 Impact Circuit Designs - All Rights Reserved.

CAGE: 1UWD4 | Veteran Owned and Operated